A professional crimping job decides whether you and the crew celebrate an incredible catch, or partake in a long, depressing and speechless ride back to the dock - and we’ve all been on both sides of that coin.

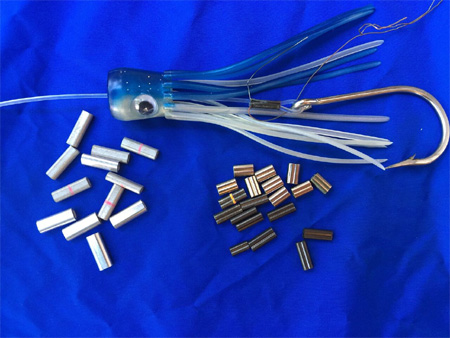

Know the correct sleeve styles and sizes for the particular types of fishing you plan on doing.

As basic as crimping seems, the “art” is anything but elementary. Crucial is selecting the correct sleeve and material, sizing it to the leader, and properly executing the connection. To keep you and your next big fish from parting ways, heed the insights below.

SIZED TO PERFECTION

– The objective of crimping, beyond forming loops and attaching hooks, is to compress a leader to where it’s virtually melded with the sleeve, without damaging it. Read: zero slippage. Hence the criticalness of closely sizing sleeve diameter to that of the leader.

Rick Mola, noted canyon angler and head of Fisherman’s World in Norwalk, Connecticut, says it’s impossible for sleeve manufacturers to offer a precise sleeve for every specific pound test mono or fluorocarbon leader, due to their differing diameters. Therefore, sleeves are grouped into broader categories, such as 1.3mm sleeves for 150 – 200 lb test mono, 1.6mm sleeves for 220 to 250 lb test mono, etc., etc.

Mola recommends the smallest diameter sleeve in which the leader can still pass through – albeit tightly, versus a sleeve that is slightly larger and easier for the line to navigate; the latter has more slippage potential. When purchasing sleeves, Mola suggests bringing in your leader material (if not also purchasing it), opening up a pack of sleeves rated for that pound test leader, and actually fitting the leader into the sleeve. Sometimes a recommended sleeve size may or may not fit precisely. It’s not unlike trying on a pair of shoes before you buy.

“Sometimes the diameter of your leader is between two sleeve sizes”, says Mola. “Like if your 200lb mono has a diameter of 1.48mm, a 1.3mm sleeve will be too small for the line to pass through. You’ll have to move up to the next size; in this example a 1.6mm sleeve. Then, even more importance is placed on the proper crimping procedure”.

TYPES OF SLEEVES

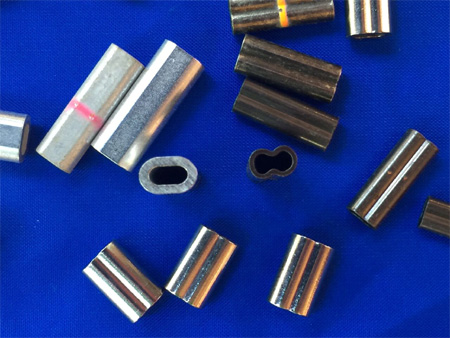

- The best-selling saltwater sleeves are the oval and double-barrel designs. There is a round sleeve, but its design and crimping make them less reliable on the heavier leaders used in the brine.

With a double barrel sleeve, popular for monofilament and fluorocarbon leaders, each leader strand rests snugly within its own chamber. The chance of the leader laying over itself is eliminated (ditto with related damage). Scaring of the leader during the crimping process is also greatly reduced, providing it’s done correctly.

Double barrel sleeves are also very popular with cable rigs - due to the exceptional bite the two metals generate. More on specific cable sleeves in a bit.

Oval sleeves are especially ideal for fluorocarbon leaders, as fluorocarbon is more oval-like in diameter than round. Therefore, they’ll compress efficiently. Ovals often get the nod for heavier fluorocarbon as well as traditionally rounder monofilament leaders used for big game fishing (large marlin, swordfish, tunas, sharks), yet they also serve well for lighter leaders and small game scenarios.

One caution with oval sleeves: make certain the leader does not lay over itself inside the sleeve prior to crimping. If that happens, severe damage may occur and jeopardize the connection.

MATERIAL THOUGHTS

- According to ROSCO’s Jack Butts (ROSCO is the largest producer of brass sleeves in the U.S.), there are only two metals used for crimps: aluminum and brass. “Nickel, zinc, and black oxide are finishes that can be plated on to a brass sleeve,” explained Butts. “These two metals are used, as opposed to stainless steel, because they are much softer and less likely to damage monofilament or fluorocarbon. We carry an imported line of aluminum sleeves, but our brass sleeves are way bigger sellers. Brass and aluminum will not react with the saltwater and, therefore, will not pit or corrode. The worst that will happen is that the finish could wear off over time.”

Big game angler Jeffrey Liederman, of Capt. Harry’s Fishing Supply and team member of “Lights Out” – the boat winning a one million dollar pay day in the 2015 Ocean City White Marlin Open, advises knowing when to use a plating, or risk tackle failure. For example, with cable leaders, like for wahoo and sharks, Liederman opts for zinc-plated sleeves, versus aluminum. The zinc-plating prevents electrolysis from the two dissimilar metals; in concept, like a zinc anode does for an outboard motor. Norwalk’s Rick Mola also uses plated brass for his metallic leaders for the same reason, plus the fact that the grip between cable and brass is superior than with aluminum. For mono and fluoro, Liederman and Mola are aluminum proponents, because aluminum shapes best to those materials and, therefore, provides the snuggest fit.

CRIMPING GAMES

– Oval and double barrel crimping tools are designed for multiple sleeve sizes, with round-like fittings. Crimpers with a notch (tooth) protruding from each fitting is designated for round sleeves. Crimping mono upwards of 200lb test is conveniently accomplished with a hand swage (crimper), whereas a bench swage is more precise and less labor intensive for fabricating leaders in excess of 200lb test.

Place the oval or double-barrel sleeve upright and onto the correct size slot at the business end of the crimping tool. It should snap right in. However, if there’s slight play, lightly align the sleeve and hold it perfectly straight until the pressure from the crimping tool takes over. Avoid crimping near a sleeve’s edge. The end of a properly crimped sleeve will blossom upward, whereas one crimped at the edge will crush the metal downward into the leader, cutting or severely damaging it. Based on the length of the sleeve, more than one compression can be applied for extra insurance.

Anglers sometimes reinforce their initial crimping job, by duplicating it within the next smaller size slot on the tool. A bit of extra compression is usually fine, but if overdone, the leader will be crushed or cut – damage which may not reveal itself until later, as a failed connection and lost fish.

For metal leaders, crimping the bitter end of a sleeve is actually beneficial. Jeffrey Liederman says it actually grips the metallic leader and further prevents slippage. Liederman will crimp in typical fashion, plus compress down one end of a sleeve. For example, the flared end of a sleeve will face the hook eye, with the compressed side facing forward. At the loop, the compressed side will face down the leader.

THE TEST

– Despite decades of canyon fishing and rigging lures for customers, Rick Mola won’t let any crimped terminal tackle system out of his store without getting beyond his final test - a heavy duty screw affixed to a desk. Mola simply attaches the connection to the screw and applies pressure. Any weakness will reveal itself at this stage. And better here than when slugging it out with a heavyweight fish. After all, everyone enjoys a festive boat ride in, especially when there’s a big fish laying in the cockpit, or release flag flying high from an outrigger.

LENGTH AND THICKNESS

- Thick walled and longer sleeves (perfect for a couple compression points as insurance) are intended more for heavy tackle, big game fishing the likes of marlin, tuna and sharks. For smaller game on lighter tackle, longer, thick-walled sleeves can “bulk up” a rig and scrub action off those baits and lures. When light tackle trolling for white marlin, sailfish or dolphin, select short, thin-walled sleeves. They’re virtually unobtrusive and won’t inhibit the action of small baits and lures.

DOUBLE-SLEEVING; WORTHWHILE?

- For many anglers, double-sleeving (using two sleeves for a connection), is like an insurance policy. Is it worth the effort? If a crimp job fails, that backup sleeve could very well save the day. Or, as Rick Mola bluntly put it: “If you don’t have confidence in your crimping ability, double-sleeve.” Double-sleeving is also good for putting more space between a hook eye and lure, like a trolling feather, for example. When creating space this way, Rick Mola adds a plastic bead between the sleeve closest to the lure and lure head. This slight bit of extra space between the sleeve and lure prevents binding and allows the hook to lay properly.

KEEPING THE COOL WITH CHAFING MATERIAL

– Adding a thimble or chafing material around the leader prior to crimping on a hook or making a loop just may save you a large fish. Thimbles and plastic tubing are commonly used buffers against any possible wear from the leader rubbing along the hook’s eye, a possibility during a long fight. However, Rick Mola says there’s more than prolonged rubbing to worry about, if you’re not using chafing gear. He says a hook can be virtually “melted” off at the leader, citing two different examples where this happened with what he believes were large big eye tuna. “I’m convinced that during a very fast and long initial run, the hook eye and leader violently working against each other create enough intense friction for the hook to actually part the leader”, says Mola. “I lost two large tunas during long first runs, and after scrutinizing the failed leaders, I swear it was the heat from the intense friction that parted them. After losing that second fish, I’ve since incorporated chafing material around the leader connecting the hook, and also around the loop at the leader’s opposite end, where the snap swivel attaches”.

FITTING TIPS

– Working a mono or fluoro leader through the correct size sleeve can be challenging, due to the tight fit. In many instances, it’s hard to get the leader started into the sleeve. By cutting the leader on an angle, reducing its initial diameter, and then moistening it with salvia, it should penetrate the sleeve fairly easily. Prior to crimping, leave a short tag end. After crimping, heat the tag end with a lighter, and blunt the end. In case of slippage, the head on the tag end may jam against or in the sleeve, and save the catch.

SLEEVE CONNECTIONS

ROSCO TERMINAL TACKLE - www.roscoinc.com

AFW HI SEAS - www.afwhiseas.com

BOONE - www.boonebait.com

BILLFISHER - www.seastriker.com